Test services

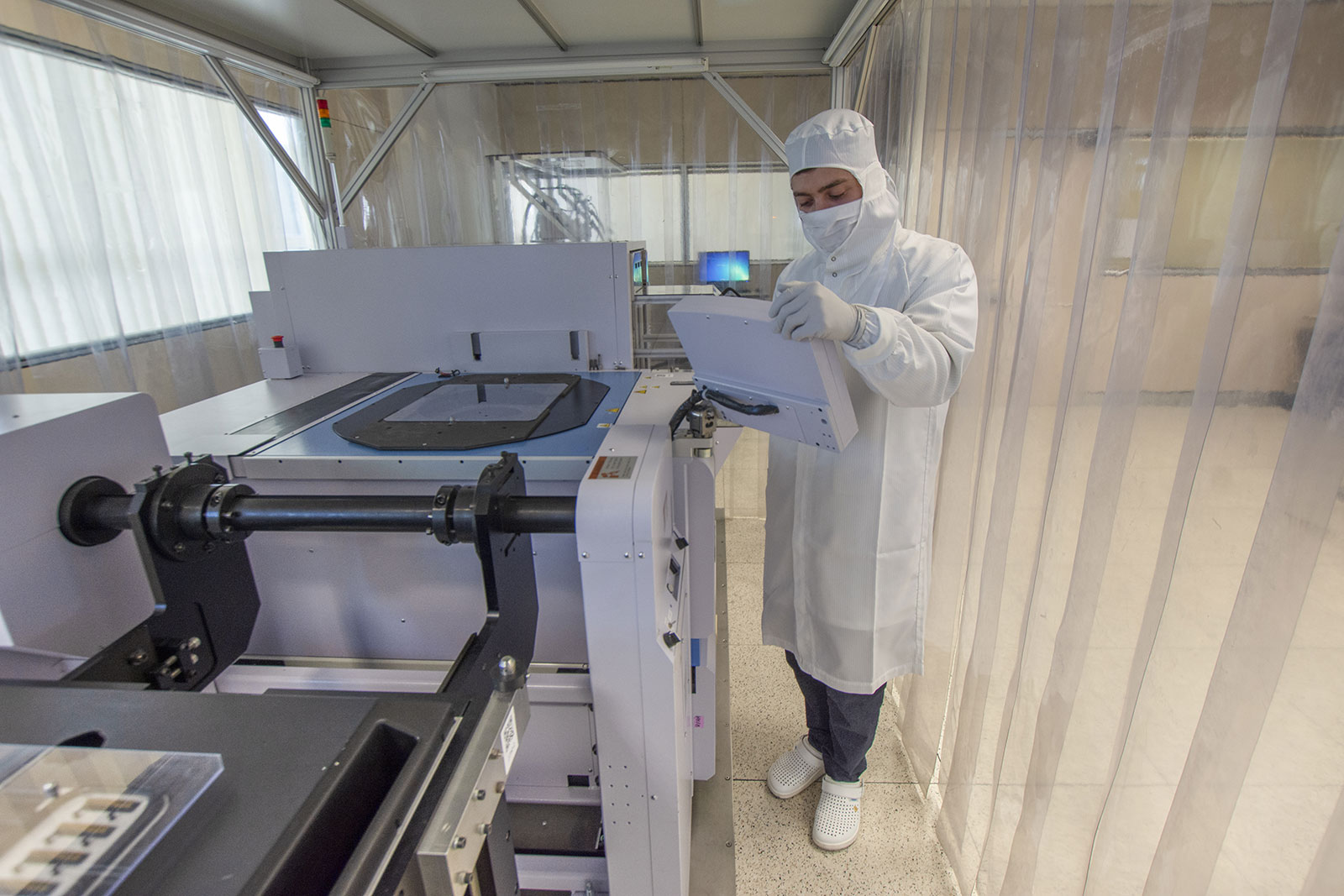

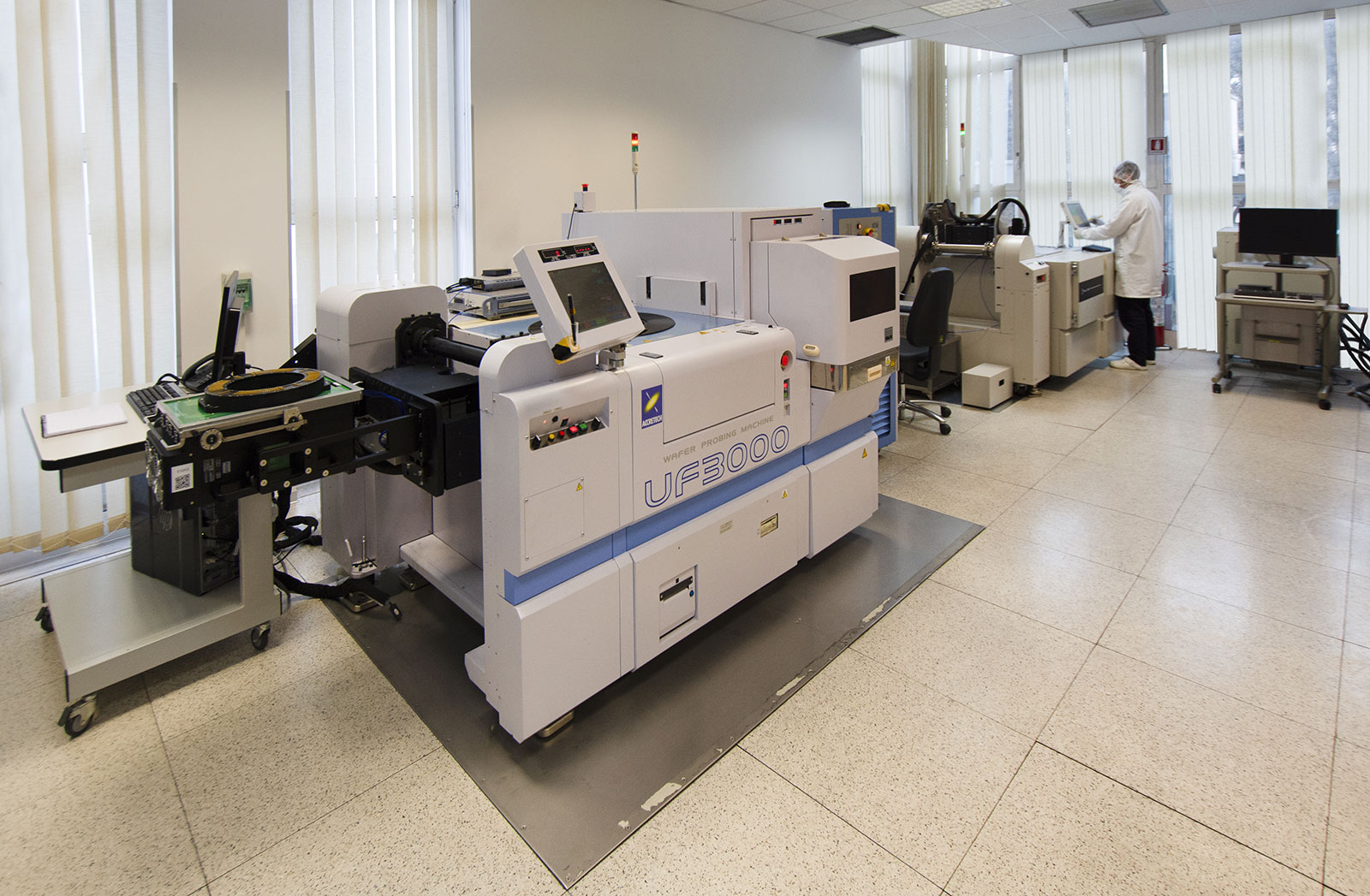

Microtest provides complete test house services in a clear room equipped with the state of the art handler and wafer probing system using its own innovative ATE.

The test house operates in hot, cold and room temperature for both production and characterization test.

Innovative reliability system for Burn In and HTOL Services

Statistical analysis is performed for digital and mixed-signal devices.

Microtest Pacific Test house is located in Malacca (Malaysia).

Activity Supported

- TURN KEY TEST SOLUTION DEVELOPMENT

- OVENLESS BURN-IN & HTOL SOLUTION

- VOLUME PRODUCTION

- RADIATION TEST

Our engineers will help you with all your needs for all the application fields:

Applications

TURN KEY TEST SOLUTION DEVELOPMENT

Highly qualified testing engineers support the customers all over the world for turn key test solution development.

State of the art tester platform availability.

- 30 years of experience in microelectronic engineering

- Knowledge in full applications, automotive, industrial, healthcare, space, consumer, RF

- State of art of used equipment (ATE, OLT, Burn-in, prober, etc.).

- Design for testability to help to reduce cost of test and improve quality

- Turn-key solution from DFT to mass production

- Continuous improvement during production phase:

- Test Time optimization

- Yield improvement

- S-PAT, D-PAT, G-PAT, Z-PAT implementation

Equipment available:

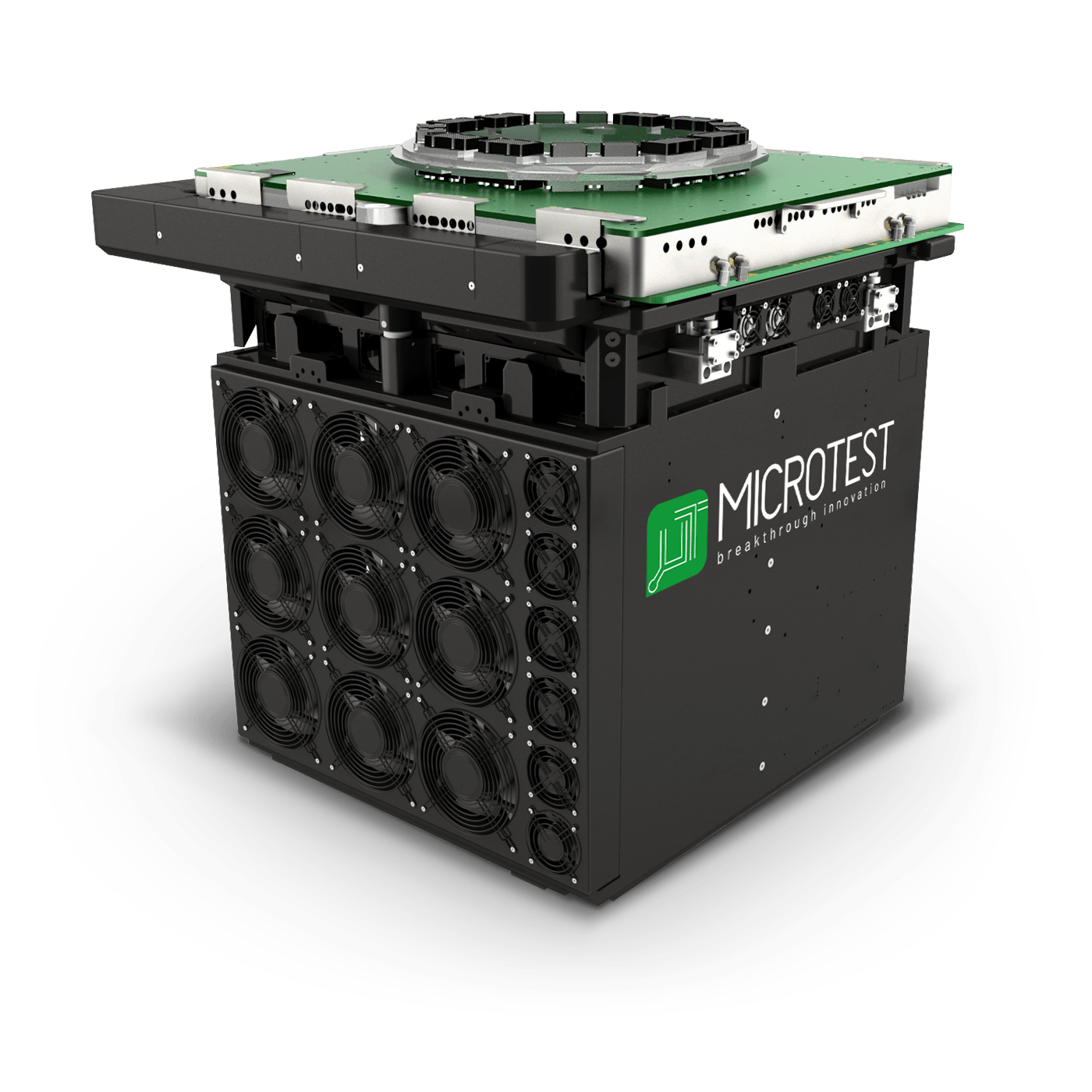

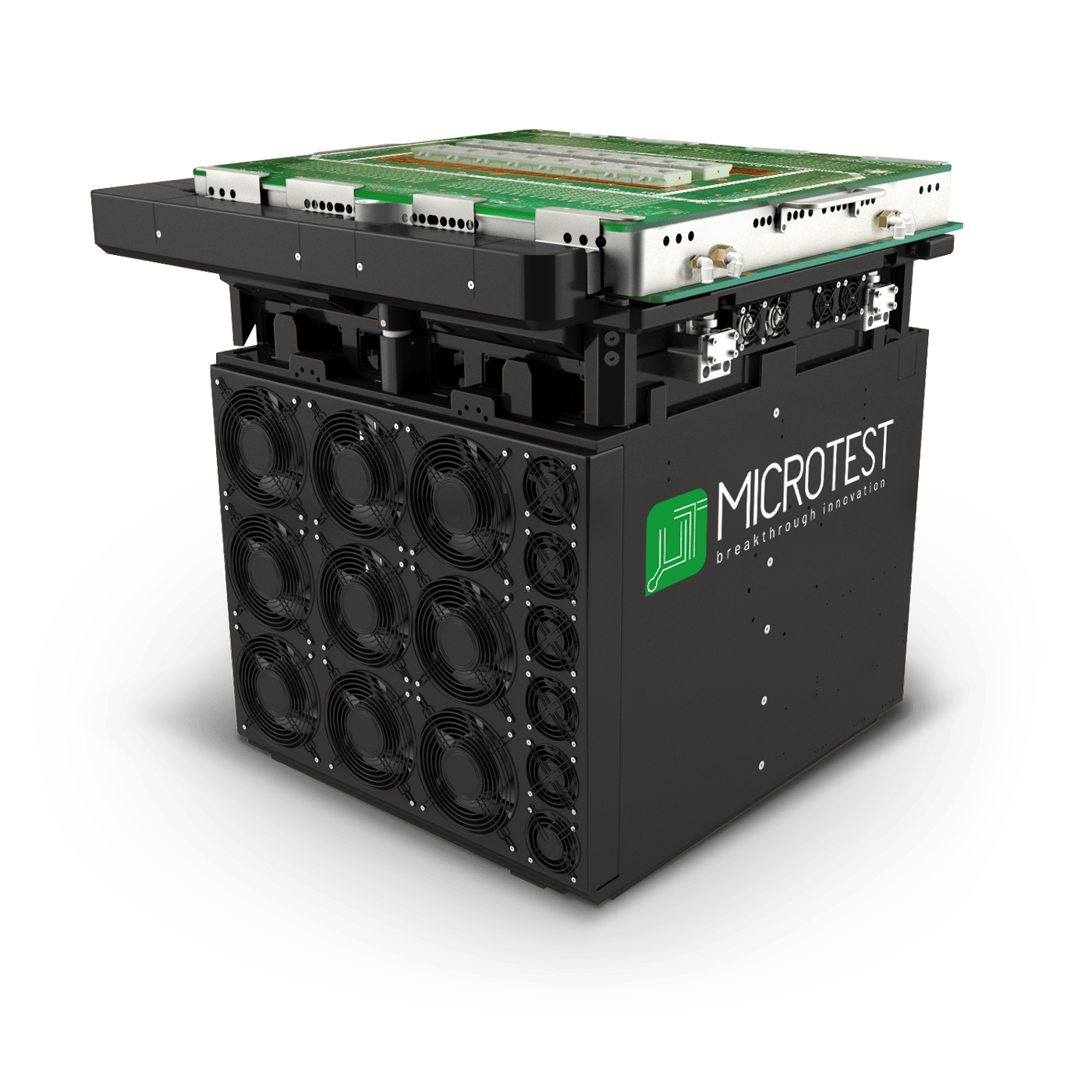

- Microtest Hatina (different configurations including uWave option)

- Teradyne A565

- Teradyne J750

- Teradyne uFlex

- Teradyne Integra Flex (with uWave option)

- High volume Microtest Celsius 3T handler

- Microtest Scara 3T handler

- Exclusive Microtest ovenless Burn-In system

- Wafer Prober from 6 to 12 inch

- Semics Opus 3

- Accretech UF3000

- Accretech APM90

- Accretech UF200

- Thermostream

Thanks to these equipment, we are able to develop the most powerful and complex test solutions for all the different application markets: automotive, industrial, consumer, space, military.

ISO9001 and automotive compliant test solution flow.

OVENLESS BURN-IN & HTOL SOLUTION

The first ovenless burn-in on the market!

Microtest Burn-in is an innovative and fully automatic solution that drastically reduce industrial costs and increase quality of test

Main feature:

- Heater embedded for each DUT

- Up to 24 Burn-in Boards per system

- Up to 120 devices per board

- Automatic loader compatibility

- Small footprint

- DUT heater independent control DUT

- Very low power consumption

- High reliability and accuracy

- Only the device at high temperature

VOLUME PRODUCTION

Microtest high skilled team of engineers is able to follow the product development from EWS to final test.

- Production engineers available for monitoring and guarantee the quality of production test.

- Quality of the test continuously checked and improved

- Test Time and Test Program optimization

- Yield improvement

- S-PAT, D-PAT, G-PAT, Z-PAT implementation

- Automatic yield loss stop control

- Automatic data analysis integrity and post processing available. Data available for the download in a secure area.

- Engineering reporting for yield loss analysis

- Possibility to test in Europe and in Far-East

- EWS, FT, hot cold and room from -70° to 180°

- Low and high volume Burn-in service

- AEC Q

RADIATION TEST

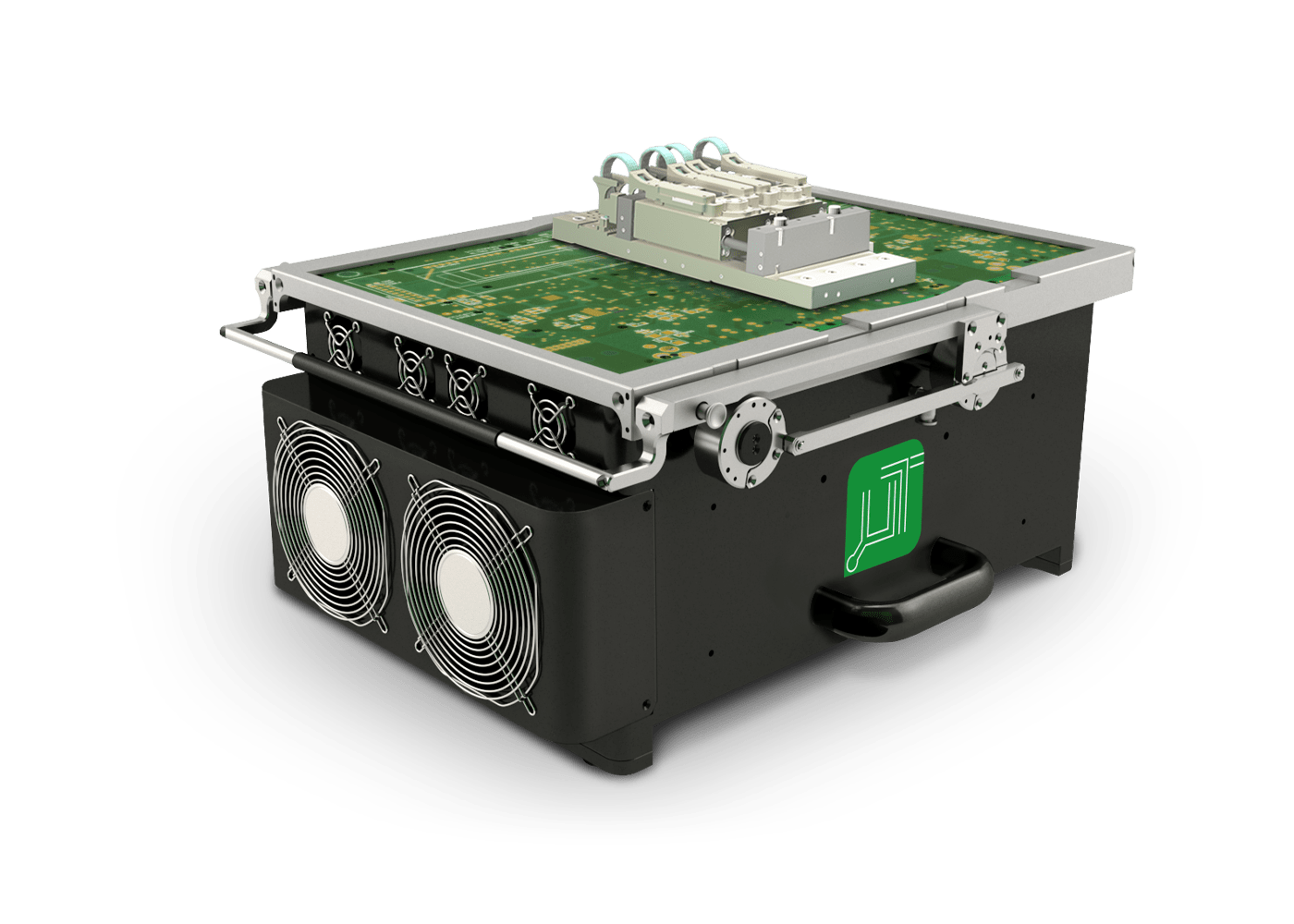

Thanks to a very small and portable ATE configuration (Hatina + DMT), Microtest allows to reuse the characterization test program during the radiation test.We can boast more than 10 years of experience on radiation test with special patented solution to heat and cold test in vacuum chambers.

- ESCC9000 compliance

- Software for real-time events monitoring

- SEE and TID on very complex mixed-signal devices

- Running cooperation with companies qualified in physics sciences for beam management

- Cooperation with INFN (Nuclear Physics National Institute)

- Access to highly qualified laboratories for radiation activity

- SEE –> RADEF (RADiation Effects Facility), Finland

- TID –> Louvain La Neuve (Belgium), , Noordwijk (Netherland), Rome (Italy)

- Standardized and consolidated radiation test flow

- Software for SEL, SET, SEU analysis directly on the facility during the irradiation

- Devices are currently flying to Mercury and Mars and several flying orbital devices

- Physics experiments are currently running in space thanks to ESC9000 qualified devices in Microtest

- Theoretical knowledge of the physics of radiation effects on microelectronic devices